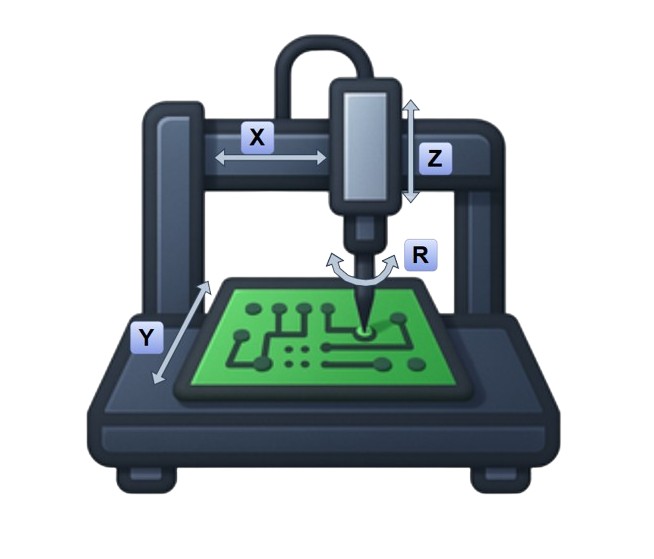

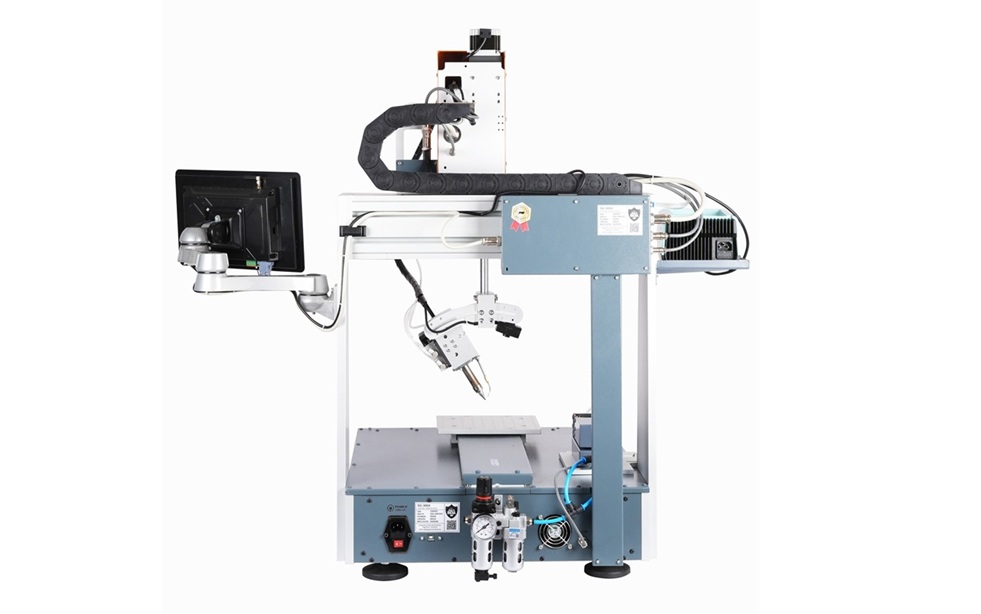

4-Axis Automatic PCB Soldering Robot

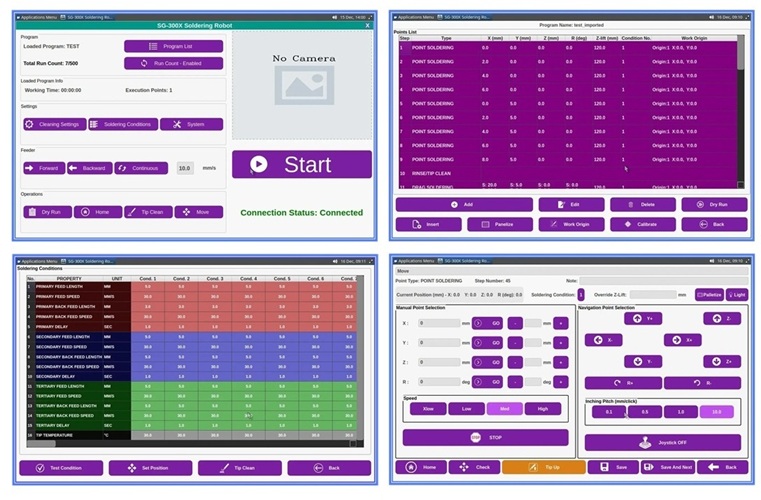

Overview

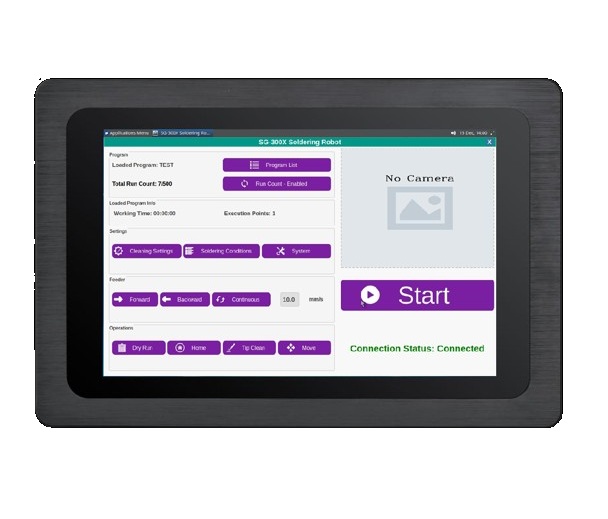

Robot combines precise soldering, easy operation, and cost-effective automation in a single platform. It delivers consistent solder quality, reduces manual dependency, and improves production efficiency, while offering features comparable to high-end imported machines with the advantage of local support and customization

Working Principle

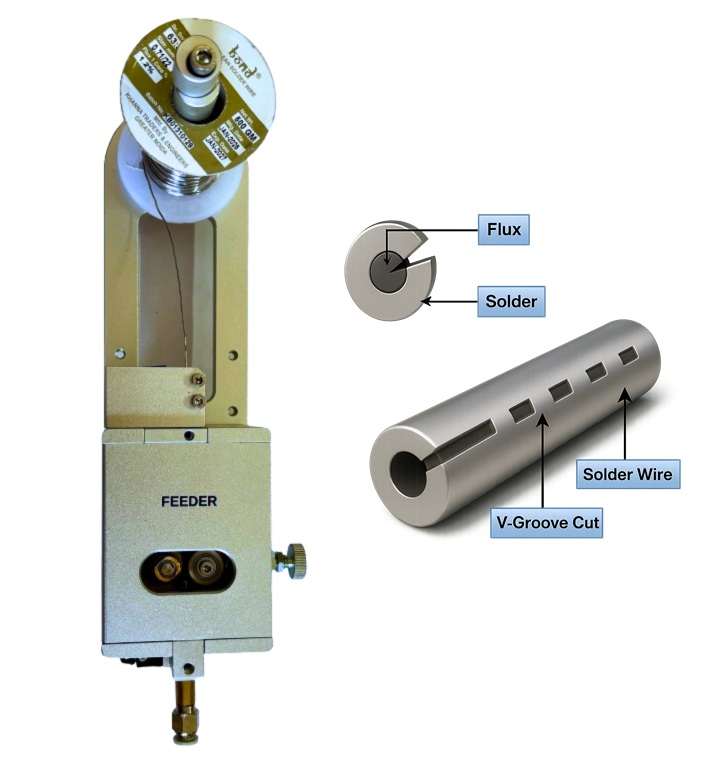

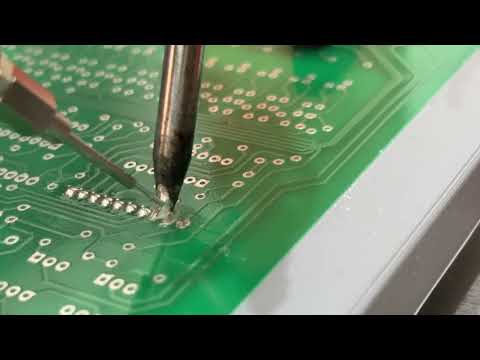

The soldering iron is mounted on a precision-controlled robotic manipulator that accurately positions the tip at predefined soldering locations. During operation, solder wire is automatically fed to the temperature-controlled tip, forming consistent and reliable solder joints at each target point.

Why Choose Robotic Soldering?

Manual soldering presents challenges such as:

- Human error and fatigue leading to inconsistent quality and reduced throughput

- Quality variability in large production runs

- High labor cost and operator dependency

- Safety hazards due to heat and fumes

The Automatic Soldering Robot overcomes these challenges by providing a controlled, repeatable, and intelligent soldering process.